FAQ of Diesel Generator Set

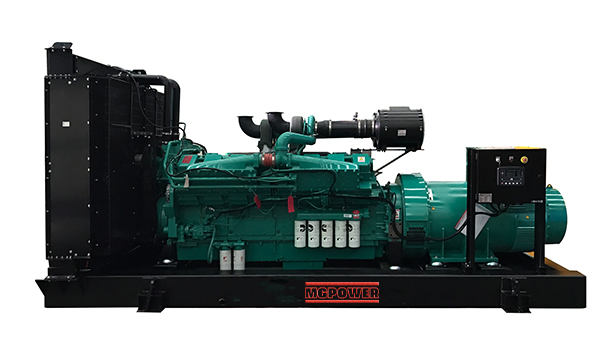

1. How many basic systems does one industrial diesel Generator Set include?

1.1 Engine System: This system includes the diesel engine that drives the alternator. It includes components such as the fuel tank, fuel system, air intake system, exhaust system, cooling system, and lubrication system.

1.2 Alternator System: This system includes the electrical alternator that produces the electrical power. It includes components such as the stator, rotor, bearings, and voltage regulator.

1.3 Control System: This system includes the control panel that monitors and controls the generator set’s operation. It includes components such as the engine controller, alternator controller, and switchgear.

1.4 Fuel System: This system stores and supplies the fuel to the engine. It includes components such as the fuel tank, fuel pump, fuel filter, and fuel lines.

1.5 Cooling System: This system circulates coolant through the engine to keep it from overheating. It includes components such as the radiator, water pump, and thermostat.

1.6 Exhaust System: This system removes the exhaust gases from the engine. It includes components such as the muffler, exhaust pipe, and exhaust manifold.

1.7 Lubrication System: This system lubricates the engine’s moving parts to reduce friction and wear. It includes components such as the oil pump, oil filter, and oil cooler.

1.8 Battery System: This system provides power to start the engine and powers the control panel when the generator is not running. It includes components such as the battery, battery charger, and battery cables.

1.9 Air Intake System: This system provides clean air to the engine for combustion. It includes components such as the air filter, air intake duct, and air intake manifold.

2. Why the new Generator Set needs to replace lub oil and oil filter after a period of use?

Lubricating oil is essential for the smooth functioning of a generator set. However, with time, the oil gets contaminated with dirt, debris, and other impurities, which can cause severe damage to the engine of generator, especially to the backup generator. This is why it’s crucial to replace the lub oil and oil filter after a certain period of use to maintain the genset’s performance and longevity.

Neglecting this maintenance can result in frequent breakdowns, increased fuel consumption, and costly repairs. So, be sure to schedule regular maintenance and replace the lub oil and oil filter as recommended by the manufacturer to keep your generator set running smoothly.

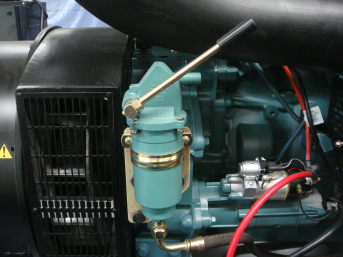

3. What is the function of manual oil pumps and exhaust bolts in diesel engines of industrial generators?

Manual oil pumps in diesel engines of DG sets are used to manually prime the oil system with oil before starting the engine. This helps to lubricate the engine and ensure that it runs smoothly.

Exhaust bolts, also known as exhaust manifold bolts, are used to secure the exhaust manifold to the engine block. They help to prevent exhaust gases from leaking out and causing problems with the engine’s performance. If these bolts are not properly secured or become loose, it can cause exhaust leaks, which can lead to engine damage and reduced efficiency.

4. Why it is not appropriate to screw the oil filter, fuel filter and water separator too tightly?

Over tightening filters can cause a range of issues, including:

4.1 Damage to the filter housing or threads

4.2 Difficulty in removing the filter during future maintenance due to a locked-in filter

4.3 Distortion of the filter seal, leading to leaks

4.4 Breakage of filter components that can cause debris to enter the engine or fuel system

4.5 Excess pressure build-up within the filter, potentially leading to a rupture in the filter casing

5. Why is the Generator Set’s outlet voltage standard 400V instead of 380V for 50Hz?

Because 400V is the nominal voltage for a three-phase electrical system, which is the most common type of electrical distribution system used worldwide. Also, modern electrical equipment is designed to operate efficiently at 400V 3 phase, while 380V is an older standard. In addition, the voltage drop in electrical cables and transformers can cause a loss of voltage, so setting the nominal voltage higher helps compensate for this loss and ensures stable and reliable power supply.

6. Why do we ask customers to incline the exhaust pipe down 5-10 degrees when installing the Generator Set?

Inclining the exhaust pipe down at a slight angle can help prevent the backflow of exhaust gases into the generator’s engine. This can help improve the overall performance of the generator and ensure that it runs smoothly without any issues.

Additionally, it can also help prevent the accumulation of moisture and debris in the exhaust system, which can cause damage to the generator over time. Overall, inclining the exhaust pipe down is a common practice recommended by many generator manufacturers to help ensure the safe and efficient operation of their equipment.

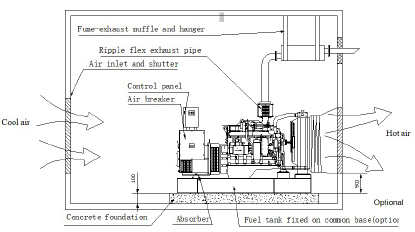

7. Why does the working site of Generator Set require sufficient air flow environment?

Because the generator set produces heat while converting fuel into electricity energy. This heat must be dissipated to prevent overheating of the equipment, which can cause damage or malfunction. Sufficient air flow ensures that the heat generated by the generator set is effectively removed from the surrounding environment, keeping it at a safe temperature. Additionally, proper air flow can help to remove any harmful gases produced by the generator set during operation, further ensuring the safety and efficiency of the equipment.

8. What is standby power and prime power of generator for sale?

Prime power of diesel genset means continuous running at variable load for unlimited periods, 10% overload available for 1 hour in every 12 hours.

Standby Power of diesel genset means continuous running at variable load in the event of utility power failure, no overload is permitted on these ratings. Normally this kind of DG set is for emergency use.

9. How to calculate the best running power (economic power) of the Generator Set?

Best Power=3/4*Rated Power (ie 0.75 times rated power).

For example, rated power is 500KVA, the best power is 500KVA*3/4=375KVA.

10. Why is Generator Set not allowed to run for a long time below 50% of the rated power?

Operating a generator set at low power levels for a long time can lead to several issues, such as :

10.1. Carbon buildup: Low load conditions in engines can cause carbon deposition on the pistons, cylinder heads, and valves. This carbon buildup can cause poor fuel efficiency, power loss, and reduced engine performance.

10.2. Wet stacking: Running a generator set at low loads can also cause a phenomenon known as ‘wet stacking’. This happens when unburned fuel accumulates in the exhaust system causing black smoke. Wet stacking can lead to issues like decreased engine lifetime and poor fuel efficiency.

10.3. Glazing of cylinder walls: Running a generator set at low loads for long durations can also lead to glazing of the cylinder walls due to incomplete combustion. This can cause an increase in oil consumption, poor lubrication, and loss of power.

10.4. Reduced reliability: Running a generator set at low load for a long time can reduce the reliability and longevity of the generator set. It can cause unnecessary wear and tear on the components and increase the risk of breakdowns.

Therefore, it is recommended to operate the generator set at or above 50% of the rated power to avoid these issues and ensure optimal performance, durability, and reliability.

11. The actual output power of the Generator Set during working is based on the power meter or the ammeter?

The actual output power of a generator during working is based on the power meter. A power meter measures the amount of electrical energy being used or generated and provides an accurate reading of the power output. An ammeter, measures the current amp flowing through a circuit and is not directly related to the power output of the generator.

12. For direct start-up load like elevator, what size of Generator Set should suggest?

The elevator is a direct start-up model with load, and the instantaneous starting current is generally 7 times the rated current to ensure that the elevator moves at a constant speed. If the motor power of elevator is 25KW, the rated power of Generator Set should be 25KW*7=175KW.