Everything about industrial generator

1. What is industrial generator set?

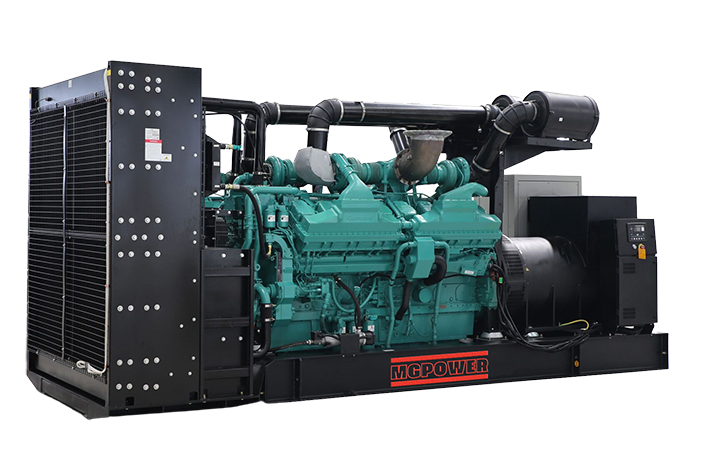

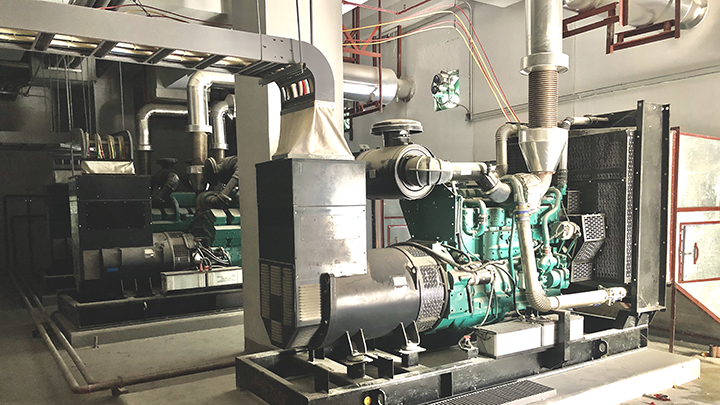

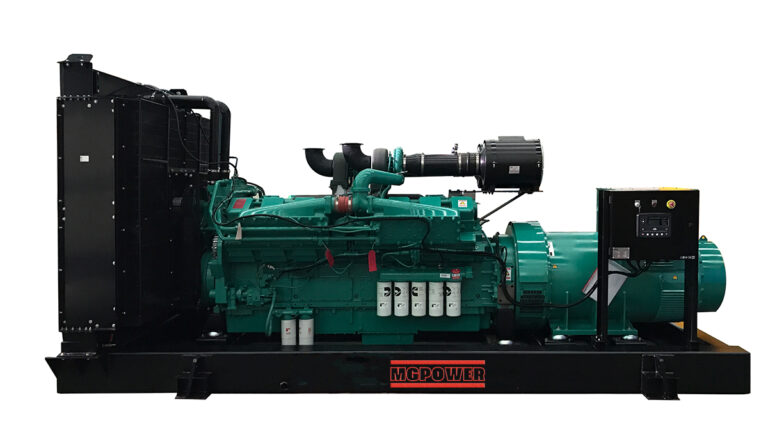

A diesel generator combines a diesel engine and an alternator to generate electricity. Industrial genset are generally large in size and can provide a great deal of power for a long period of time. As the name suggests, they are generally used in industries where power demand is high. MG industrial genset are widely applied in power plants, data centers, real estate, construction, telecom, mining, hospital, etc.

2. Why do you need industrial generator?

An industrial generator mainly consists of a diesel engine and an alternator which is changing the mechanical kinetic energy into electrical energy. A diesel industrial generator can be used for different applications such as an emergency power supply in case of power cuts in a city or continuous power supply in remote areas without any power grid.

3. What is the specification of industrial generator?

3.1 Power Capacity – It is very important to know the load requirement of the factory or office before buying a diesel generator set. MG Power offers comprehensive solutions ranging from 10 kVA to 4000 kVA.

3.2 Phase – Diesel generator sets are available for single phase, two phases, and three-phase connections. Check the power connection in your factory or office and choose a suitable generator set accordingly.

3.3 Fuel Consumption – Fuel consumption is also one important thing you need to consider for daily use costs. Find out the fuel consumption of the generator set per hour and per KVA (or KW) and also the fuel efficiency it provides with respect to the load.

3.4 Control System – Diesel generator sets installed with an intelligent control system can transfer power automatically from the grid to the generator set during a power cut and vice versa. And LCD screen in the control system displays analysis data such as oil pressure, load, speed, voltage, frequency, water temp, etc., which helps to optimize the performance of the diesel generator set.

3.5 Portability and Mobility – A generator set can be installed with a mobile trailer base in 2 wheels or 4 wheels depending on the size of the generator set for short-distance low-speed movement of mechanical equipment. It is mainly used for outdoor work platforms with special equipment.

3.6 Noise and Emission – High noise or smoke emission can be a problem to current environmental requirements. Noise and emission reduction design is necessary to meet the market requirement. MG Power has developed our unique silent type diesel generator sets with good noise reduction performance and reasonable prices based on years of experience and user feedback.

4. What is the power range of industrial generator?

MG power industrial generators are ranged from 9-3750KVA by different product series. There are 5 product series according to engine brands.

Cummins Engine Series: 25kVA-1650kVA 50Hz and 30kVA-1875kVA 60Hz. Cummins engines are made in China.

Perkins Engine Series: 9kVA-2500kVA 50Hz and 11kVA-1875kVA 60Hz. Perkins engines are mixed with China, India, US and UK made.

MTU Engine Series: 750kVA-3250kVA 50Hz and 815kVA-3750kVA 60Hz. MTU engines are mixed with China and Germany made.

Doosan Engine Series: 150kVA-825kVA 50Hz and 188kVA-935kVA 60Hz. Doosan engines are all made in Korea.

Yuchai Engine Series: 25kVA-3250kVA 50Hz and 38kVA-2250kVA 60Hz. Yuchai engines are all made in China.

For each engine series, it also match with different brands of alternator like Stamford, Leroy Somer, Mecc Alte and MG own brand. All the alternators are made in China.

5. What is the structure of industrial generator?

MG power has 4 different structure types for different applications and different users’ requirements. They are open type, silent type, mobile trailer type, and containerized type.

Open type: MG power all series industrial generators could be made into open type, adopting Cummins, Perkins, MTU, Doosan, and Yuchai engines, which power range is 10-4000kVA. Open-type industrial generators are basic, economical, use-convenient, power strong, and easy to maintain, especially suitable for the situation without any special request for noise control.

Silent Type: MG power silent type industrial generators adopt soundproof and weatherproof canopy. The unique design of the air inlet and outlet system lowers the noise of industrial generators obviously, which could reach 65-75dbA/7m with full loading.

MG silent type industrial generators are powered by Cummins, Perkins, MTU, Doosan, and Yuchai engine series. The power range is 10-4000kVA. The unique canopy design is stronger in structure and better in heat dissipation, which is excellent for industrial and commercial use. In addition, MG uses various complicated design to control the noise according to many years of experience and feedback from users.

Mobile Trailer Type: MG power trailer type industrial generators are mainly used for specialized operation platforms outdoors and also for the low-speed move of mechanical equipment over short distances. Easily moving makes the industrial generators especially suitable for outdoor construction sites, like road and railway construction and temporary electricity utilization.

MG power trailer-type industrial generators adopt Cummins, Perkins, MTU, Doosan, and Yuchai engines as power sources for ensuring stable performance and easy maintenance.

Containerized Type: MG power containerized type industrial generators use advanced sound-absorbing materials and scientific and unique design in airflow and noise control. The container is with CSC certification, in line with international container security conventions, ensures shipping directly as a standard container, and greatly saves the cost of transportation. According to industrial generators’ dimensions, below 1000 KVA, it will use ISO 20’ft GP or HQ container and 40′ HQ container for above 1250KVA.

6. What do you need to know before buying industrial generator?

6.1 Industrial or Residential – MG industrial generator sets are generally large in size and can provide a great deal of power for a long period of time. As the name suggests, they are generally used in industries where power demand is high. On the other hand, residential generators are small in size and provide power up to a specific range. They are ideal for use in households, small shops, and offices.

6.2 Air cooled or Water cooled – It is normally referred to as the diesel engines in generator sets. Air-cooled engines rely on air to provide the cooling function. Except for an air intake system being used, no additional part. Water-cooled engines rely on water for cooling and comprise of a separate system for achieving this function. So generator sets with water-cooled engines require more maintenance than air-cooled.

6.3 Power Output – The power output range of diesel generator sets is very wide and can be classified accordingly. A 5 KVA diesel generator set can be used for small loads such as air conditioners, computers, illuminations, etc. They are suitable for use in small offices, shops, and houses. Whereas a 2000 KVA diesel generator set would be suitable for use in big industries or factories with high power demand.

7. What do you need to know when you use industrial generator?

7.1 Preparation before starting – Before starting an industrial generator, it is necessary to check whether the cooling water or antifreeze in the radiator is sufficient. If it is lacking, it must be filled up. Pull out the oil dipstick to check whether the lubricating oil is lacking. If it is lacking, add it to the specified “static full” scale line, and then carefully check whether there are hidden faults in the relevant parts.

7.2 It is strictly forbidden to start the generator with load – Before starting MG industrial generator, it should be noted that the circuit breaker must be closed. After the ordinary diesel engine is started, it needs to go through 3-5 minutes of idling operation (about 700 rpm). The temperature in winter is low, and the idling time should be appropriately extended for a few minutes. After the diesel engine is started, it is necessary to observe whether the oil pressure is normal and whether there are abnormal phenomena such as oil leakage and water leakage. If there is no abnormal phenomenon, increase the speed of the diesel engine to the rated speed of 1500 rpm. At this time, the generator shows a frequency of 50HZ (1800 rpm at 60Hz), and the circuit breaker can be closed and put into use.

The generator is not allowed to run without load for a long time. (Because the long-term no-load operation will make the diesel fuel injected from the diesel engine fuel injector not completely burned, resulting in carbon deposition, resulting in air leakage of the valve and piston ring.)

If it is an automatic start generator, it does not need to run at idle speed, because the automatic generator is generally equipped with an engine heater, so that the diesel engine cylinder block is always kept at about 45 ℃, and the diesel engine can be powered normally within 8-15 seconds after it is started.

7.3 Pay attention to observe the working status in operation – During the work of the generator, there must be a special person on duty, and often pay attention to observe a series of possible failures, especially the changes in oil pressure, water temperature, oil temperature, voltage, frequency and other important factors. In addition, it is necessary to ensure that sufficient diesel fuel is available. If the fuel is interrupted during operation, it will objectively cause a load stop, which may cause damage to the generator excitation control system and related components.

7.4 It is strictly forbidden to stop with load – Before each shutdown, the load must be gradually cut off, then the circuit breaker of the generator should be turned off, and finally the diesel engine should be decelerated to idle speed for about 3-5 minutes before shutdown.